It is a lot more advanced route to take, but provides huge cost savings and much tighter integration if you were to actually use it. Supports G-Code and other programming methods and has lots of kinematics options, including all the major ABB robots since ABB bought B&R. The B&R route is how you would control a robot (or several) directly from the PLC without a controller. The ABB and Fanuc routes are simply the two largest robot vendors and show you what you could expect if you were the guy setting up a traditional robot controller for a 6-axis (or delta or whatever in ABB's case).

#Fanuc robotstudio trial#

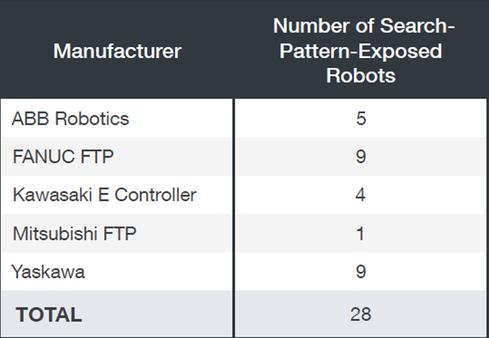

B&R Automation Studio and Scene Viewer - Free 30 day trial with online registration, can renew endlessly.Fanuc RoboGuide - 30 Day Trial that you must ask them for.If you just want to try something out, there are three routes I would suggest. Covering a diverse range of applications and industries, FANUC robots are easy to operate and provide complete flexibility thanks to a range of application-specific options, straightforward integration, payloads up to 2.3 t and maximum reaches up to 4.7 m. Robotics, like PLCs themselves, are very brand specific. With more than 100 models, FANUC offers the widest range of industrial robots in the world. Please click "report" on spam Related sub-reddits: (*) At mods' discretion, certain self-promotion submissions from people who contribute to this sub in other ways may be allowed and tagged with the "Self-promo" flair Job offers and requests go to the weekly thread.

0 kommentar(er)

0 kommentar(er)